KÜNDIG diagonální brusný agregát

Záznam uvidíte za

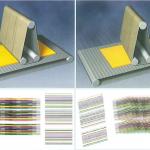

Name of a lengthwise sanding aggregate, which is set 10° diagonal to the workpiece feed direction, invented by Kündig. Sanding belts get the smallest signs of wear when being used, which show in the sanding result. When using a sanding belt set parallel to the feed direction they show from the beginning to the end of the workpiece, if the oscillation is turned on, in form of wavy lines. With a sanding belt set slightly diagonal to the feed direction, the errors form diagonal tracks, which appear as an area because of their juxtaposition. Because of the diagonal set, more abrasive particles have the opportunity to show on the workpiece then with a straight set of the sanding aggregate. Thus, there is a more thorough mixing of the tracks, which visually gives a "flat" appearance. Due to the slightly angled cut, the fibers are sheared off crosswise what leads to a clean cut and saving of energy. Advantages

These effects cannot be achieved with diagonally loaded workpieces. Alternative terms

|  KÜNDIG diagonální brusný agregát KÜNDIG diagonální brusný agregát

| |||||

CNC obrábění895

Opracování hran632

Pílení438

Hoblování188

Frézování181

Vrtání, Dlabání135

Lisování, Spájení201

Broušení323

Dopravníky, Skladování, Balení202

Povrchová úprava152

Výrobní linky127

Topení, Sušení, Drcení62

Odsávání, Stlačený vzduch, Vakuum135

Technika montáže, pracovní stoly15

Soustružení29

Nástroje, Ostřeší91

Ostatní, Příslušenství132