Nůžkový podavač

Záznam uvidíte za

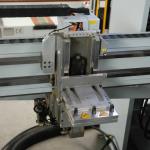

Joinery MachineThe finger gripper in joinery machines delivers the workpieces to the machining units in dimensional accuracy. The gripper, which is installed in a wagon, clamps onto the workpiece from above or below and takes it over the rollers of the machine table. Regripping takes place during the processing of long workpieces meaning the workpiece will be held on the table via a pressing fixture, the gripper lets go off the workpiece, goes back and regrips the workpiece again. The pressing fixture releases the workpiece and the processing can be continued. This is the workpiece feed most frequently used on joinery machines. Optimizing cross-cut sawWorkpiece clamping, positioning and feeding device at optimizing plants Advantages of grippers in comparison to a mere pusher

Technical realisation

CNC machining centresIn certain CNC-machining centres the clamping and movement of worpieces is executed by clamp grippers. In the middle of the 2000s, a new machine concept was established where the workpiece is not clamped tightly on a table, but is moved through the machine and thus appears as own CNC axis. Pioneer of this technology was the model Skipper by Biesse, shortly after Weeke introduced a comparable system: the BHX. Machines, in which a C axis is realized by the movement of workpieces, were already available in the 1990s, for example the relatively successful CNC boring automat of SCM. However, a wide use was achieved by launching the clamp gripper as transport device. Other solutions moved the workpiece by using transport carpets and belts, which included the danger of unprecise positioning. The clamp grippers, yet, clamp the workpiece tightly and position it via high-precision gears. Ses also: Vertical panelsawsGrippers are holding the processed panel at a precise hight, allowing automated bottom edge cutting. |

CNC obrábění895

Opracování hran632

Pílení438

Hoblování188

Frézování181

Vrtání, Dlabání135

Lisování, Spájení201

Broušení323

Dopravníky, Skladování, Balení202

Povrchová úprava152

Výrobní linky127

Topení, Sušení, Drcení62

Odsávání, Stlačený vzduch, Vakuum135

Technika montáže, pracovní stoly15

Soustružení29

Nástroje, Ostřeší91

Ostatní, Příslušenství132