Mambránový lis

Záznam uvidíte za

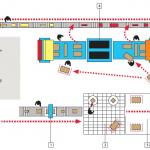

In membrane presses, coating materials such as veneer, thermoplastic films or transfer finish foils are pressed to pre-glued, profiled surfaces or shaped parts. Technical principleBefore processing in the press, the workpieces have to be prepared. This includes the application of an adhesive layer - e.g. by a spraying device or by rollers - with prior cleaning of the adhesive surface (e.g. with brushing machines). The adhesive is then dried and later in the press activated by heating. If self-adhesive films are used, the application of glue to the workpiece is deleted. The prepared workpiece is further processed as follows:

See also: |

CNC obrábění895

Opracování hran632

Pílení437

Hoblování188

Frézování181

Vrtání, Dlabání135

Lisování, Spájení201

Broušení323

Dopravníky, Skladování, Balení202

Povrchová úprava152

Výrobní linky127

Topení, Sušení, Drcení62

Odsávání, Stlačený vzduch, Vakuum135

Technika montáže, pracovní stoly15

Soustružení29

Nástroje, Ostřeší91

Ostatní, Příslušenství132