Guide to edge banding machines | 4

Záznam uvidíte za

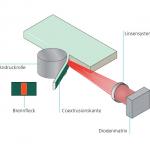

How is the state of the development with gluing technology?EVA-melting glue in form of granulation or cardridges is still circulating as always. Since 2010 we've been observing an increasing demand for machines, which are also able to process PUR-glues. Around the same time back then the new laser technology has been massively advertised which has only been interesting for industrial production. The high acquisition costs as well as complicated handling were and are not suitable for handicraft businesses. In 2015 we've sold the first used edgebanding machines with a laser. The demand of laser technology has significantly dropped in the last two years. My assumption is that in the meantime further developed hot air technology and also NIR (Near Infrared Radiation) have filled the gap. Which gluing technology is the right one for my business?Every single technology has its benefits and disadvantages. In the handicraft field I'd highly recommend PUR-machining in addition to EVA-adhesive, especially if bath or kitchen furniture is being produced. For most users a quick possibility of change between different glue colours and/or glue types can be of interest. (Keywords: quickchanging glue pot, comfort glue pot discharge, cardridge system). Whether the machine is also to be equipped with zero joint technology relevant for the handicraft (hotait, infrared) determin the orders on the table and of course also the budget. At least hot air units can be equipped with most machine also with acceptable effort. |

CNC obrábění893

Opracování hran630

Pílení438

Hoblování188

Frézování181

Vrtání, Dlabání135

Lisování, Spájení201

Broušení321

Dopravníky, Skladování, Balení200

Povrchová úprava152

Výrobní linky127

Topení, Sušení, Drcení62

Odsávání, Stlačený vzduch, Vakuum134

Technika montáže, pracovní stoly15

Soustružení29

Nástroje, Ostřeší91

Ostatní, Příslušenství131