Guide to CNC machining centres | 4

Záznam uvidíte za

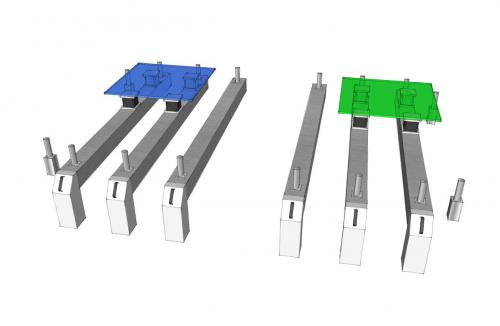

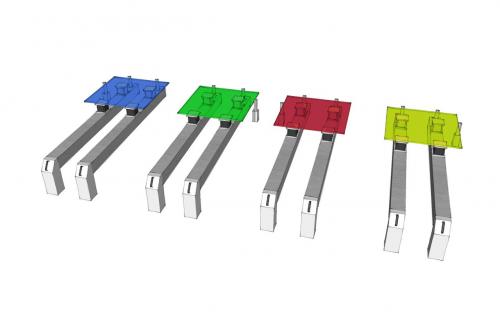

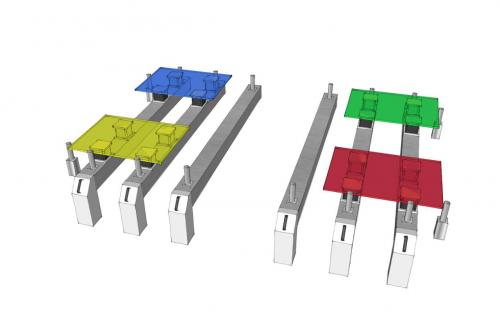

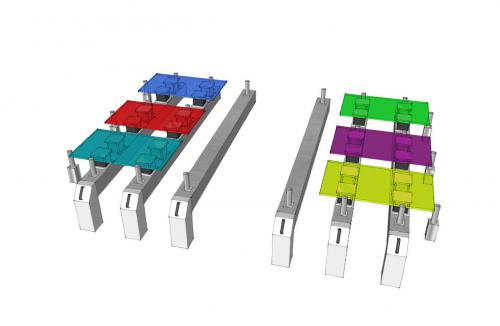

Stops and working fieldsEven a machine with three stop rows and thus the possibilty of placing the workpiece at six different positions, often has only two workpiece's reference points and two working spheres. This means that one may choose among 6 positions where the workpiece is to be placed at, but only 2 workpieces can lie on each other simultaneously. In order to be able to process more workpieces simultaneously to a clamping, the possibility of 4-field processings is being offered. These can be the four exterior edges. This arrangement proves rather practical with smaller machines with longer Y-axis. Usually every working sphere also has a separate vacuum supply. With this configuration it's necessary to have two vacuum circuits on one pod and rail table. This is relatively elaborate, hence there's another arrangement which can be found more often: there's each a stop in the middle of the machine table. These middle fence are to be easily demountable or engulfed when using large workpieces on the entire machine table. The arrangement of four work spheres next to each other offers mostly an especially-efficient occupancy of long machine tables with a lot of pod and rail tables. There are several more possibilties given with multi-field processing, e.g. 6-field processings when usind three stop rows or 8-field processing when using four outside edges and one additional middle fence. In such cases the machine has mostly only two separate vacuum circles for each machine half in command. In combination with a dual circuit vacuum system the workpieces can still be individually processed. Pendulum machiningA special form of production with several working fields is pendulum machining. On one side of the machine table production is happening, whilst on the other side of the table the setup is happening. With the pendulum machining there are several details to be considered which may heavily restrict the machining possibilites. Machines with safety devices such as shut-off mats or light barriers have a safety area in the middle of the working sphere which can only be accessed by the operator. Accordingly, the machining should also only take place in a way that the covering of the portal can never collide with the operator in the other working sphere. This can lead to a large, unusable area of more than a metre length to be created in the middle of the working sphere. The safety range can be significantly smaller with bumpers though usually the working spheres are already determined with each half of the machining table. For many years various manufacturers have offered a flexible solution where according to workpiece measurements a working sphere can be larger than the next one when occupying it. Only in this way a working sphere of a machine can be used completely flexibly and almost in full range for pendulum processing. Another point should be considered during pendulum machining: Many machines can be equipped with tool changers affixed laterally on the machinbed. The changers cannot always be reached during pendulum machining, e.g. when the changer is on the right side whilst machining takes place on the left side. Here the portal cannot access the area in which the operator is at the moment. Thus the tool changer is not possible. In any case one should make sure to have at least one changer going along on the machine when pendulum machining is taking place. |

CNC obrábění895

Opracování hran624

Pílení437

Hoblování186

Frézování179

Vrtání, Dlabání134

Lisování, Spájení202

Broušení321

Dopravníky, Skladování, Balení198

Povrchová úprava151

Výrobní linky125

Topení, Sušení, Drcení63

Odsávání, Stlačený vzduch, Vakuum140

Technika montáže, pracovní stoly15

Soustružení29

Nástroje, Ostřeší91

Ostatní, Příslušenství131