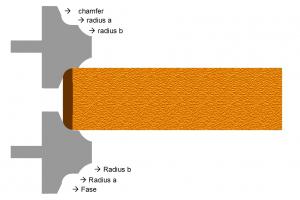

Corner rounding unit of the manufacturer HOMAG for use on industrial edgebanders

- for machining the edge protrusions on the top and bottom edge of the workpiece and for corner rounding the front and rear edge.

- servo-controlled motion sequence with soft-touch function

- 2 motors each 0,4 kW, 200 Hz, 12000 1/min

- tool holder HSK 25

- equipped with diamond milling tools and integrated suction technology

- constant rotation speed of the milling motors

- compact milling head with integrated dust extraction system

- quick-change unit for manual profile change

- longitudinal milling and / or corner rounding, free selectable via the machine controls

- motor adjustment to different edge profiles (radius/chamfer)

- workpiece feed variable 8 - 20 m/min

- workpiece length min. 120 mm + profile depth

- workpiece thickness 8 - 100 mm

- edge thickness max. 3 mm

- a separate interchangeable head is required for each tool

- shape milling of veneer and solid edges is only possible to a limited extent

- motor adjustment for different edge thickness

- motor adjustment the sensing roller front edge and rear edge processing

- variable touch pressures can be stored via programme

- optimization of the contact pressure for the processing sensitive materials

Equipment option

HOMAG flexTrim

- equipped with 2-stage trimmers for chamfering, radius milling

- functionality selectable from the control panel 2 working positions

- Position 1 - profile milling

- Position 2 - profile milling

- Position 1 or Position 2 are also used for chamfer milling milling of thin edge

HOMAG MF 60 SERVOTRIM Multifunctional trimming unit with corner rounding

HOMAG MF 60 SERVOTRIM Multifunctional trimming unit with corner rounding