SCM X-Vacuum

Záznam uvidíte za

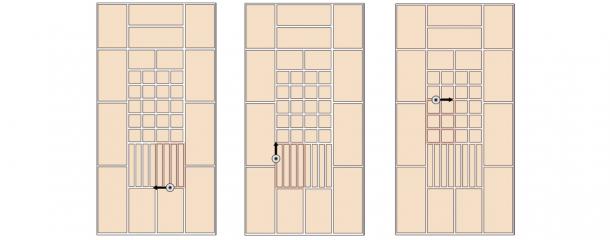

SCM X-Vacuum is a function for nesting machines. It goes back to a system for automatic multi-zone vacuum of the company BES Butzer Engineering, which no longer exists today. Problem:Nesting machines require vacuum pumps with a very high flow rate, since air permanently escapes through the protection board. The more cuts that are made during nesting, the higher theflow rate must be, as considerably more air escapes through the cuts than where a dense panel is fully supported. This has an enormous effect on energy consumption, especially when nesting small parts. Function of X-vacuum:However, since vacuum is only required to hold the workpiece, the vacuum is in principally only required where milling is performed. At X-Vacuum the work table is divided into up to 30 vacuum zones. The control system automatically determines where the router head is located and which path it will move. Accordingly, only the vacuum zones required for workpiece fixing are switched on and off. At the same time as X-Vacuum, SCM X-Pod was also developed, since the concentration on individual small vacuum zones makes it much easier to use suction cups directly on the protection board. Often the X-vacuum system is combined with a roller pressure for the processing of two plates lying one above the other (double-part processing). |  SCM X-Vacuum SCM X-Vacuum |

CNC obrábění896

Opracování hran627

Pílení437

Hoblování187

Frézování181

Vrtání, Dlabání135

Lisování, Spájení202

Broušení321

Dopravníky, Skladování, Balení198

Povrchová úprava152

Výrobní linky127

Topení, Sušení, Drcení63

Odsávání, Stlačený vzduch, Vakuum140

Technika montáže, pracovní stoly15

Soustružení29

Nástroje, Ostřeší91

Ostatní, Příslušenství131