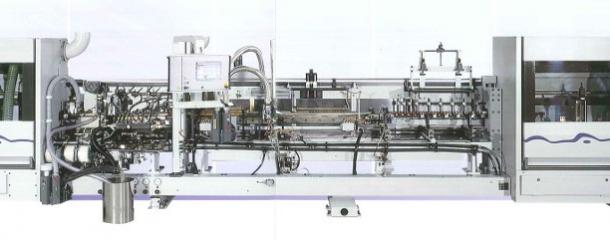

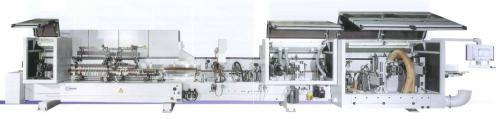

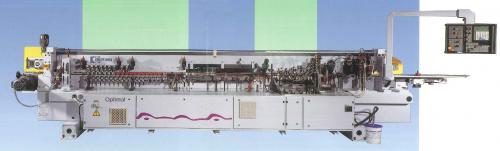

Series of through-feed Postforming machines from the manufacturer Homag

Machine design

Conventional through-feed process

| Pre-processing zone | Parallel milling of the coating material |

| Glue application zone | Application of all common types of glue (EVA glue, Polyolefins, PUR glue, PVAC wood glue) using electronically controlled nozzles over the entire height of the profile or using a glue roller, for simple profiles |

| Heating zone | Heating of the coating material, pre-drying using individually adjustable heat lamps and air nozzles |

| Deformation zone | Applying of the coating material by means of bending rod and pressing on with individually selectable pressure rollers. |

| Post-processing zone | Flush milling, grooving, buffing, insertion of piping |

Direct Postforming

For direct Postforming, normal, coated wood-based panels without any excess coating material are used. Accordingly, the pre-processing zone is extended by aggregates which expose the coating material.

| Pre-processing zone | Exposing and parallel milling of the coating material |

| Glue application zone | Application of all common types of glue (EVA glue, Polyolefins, PUR glue, PVAC wood glue) using electronically controlled nozzles over the entire height of the profile or using a glue roller, for simple profiles |

| Heating zone | Heating of the coating material, pre-drying using individually adjustable heat lamps and air nozzles |

| Deformation zone | Applying of the coating material by means of bending rod and pressing on with individually selectable pressure rollers. |

| Post-processing zone | Flush milling, grooving, buffing, insertion of piping |

Type overview

| VFL 70 | conventional through-feed method, feed rate max. 30 m/min, workpiece thickness max. 60 mm, laminate overhang max. 105 mm (depending on aggregate) |

| VFL 74 | conventional through-feed method, feed rate max. 18 m/min, workpiece thickness max. 45 mm, laminate overhang max. 80 mm |

| VFL 75 | conventional through-feed method, feed rate max. 18 m/min, workpiece thickness max. 45 mm, laminate overhang max. 110 mm |

| VFL 10 | conventional through-feed method and direct post-forming process, rolling chain, feed max. 30 m/min earlier model years 40 m/min, workpiece thickness max. 60 mm, laminate overhang max. 110 mm |

| VFL 310/5 | conventional through-feed method and direct post-forming process, floating chain, feed max. 18 m/min, workpiece thickness max. 45 mm, laminate overhang max. 110 mm |

| VFL 310/8...12 | conventional through-feed method and direct post-forming process, sliding chain, feed rate max. 30 m/min, workpiece thickness max. 60 mm, laminate overhang max. 110 mm |

HOMAG VFL

HOMAG VFL