Rubber rollerWide belt sandersUnlike inflexible steel rollers, different sanding results can be reached depending on the hardness of the rubber. The hardness of the rubber is measured and given in °Shore (degrees Shore). The hardness of rubber rollers is measured according to the Shore A-scale according to DIN 53505. In this measurement, it is determined how deep a metal tip with a defined shape can be pushed into the rubber. The lower the hardness in Shore, the softer the rubber. Rubber rollers as well as steel rollers are usually ribbed (among other uses, for holding the sanding dust, for cooling and for harmonization of the sanding structure). Guideline on rubber hardness for wood sanding:

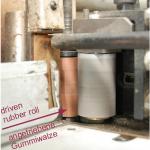

EdgebandersPart of the coil magazine of edgebanders, which is used for feeding the edge strips in form of a roll from the magazine into the gluing zone. Related and advanced terms |

CNC machining centres, robots894

Edgebanding, edge processing630

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines201

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131