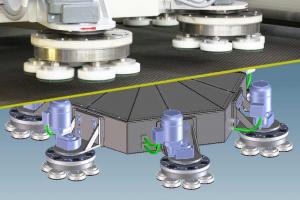

WEBERSanding pad aggregate"CBF" stands for cross belt finish on the wide belt sanders by manufacturer Weber This patented sanding technology was first introduced at the Ligna in 2005. constructionThe basic construction equals a longitudinal grinding sanding pad unit and combined sanding unit mit segmental pressure pad. In this unit a wide belt station goes transversal to the advance direction. The wide belt station proceeds between the sanding belt and the pressure element of the segmental pressure pad. Within the wide belt sanding station a cross-running chevron belt is installed, which is used in connection with the segmented pressure bar. Similar to a cross sanding unit it runs without control and its wear is uniform. EffectThe effect of the abrasive grain on the workpiece is again and again interrupted because of the diagonally profiled surface of the chevron belt. This leads to workpieces that are free of oscillation traces which have been sanded with a cross sanding unit. At the same time, the constantly alternating pressure prevents the surface from heating up too much and thus, a gluing of the sanding belts when processing lacquer and plastic panels. advantage

|  WEBER WEBER

| |||||

Images

Product brochures and leaflets (1)

Aggregates