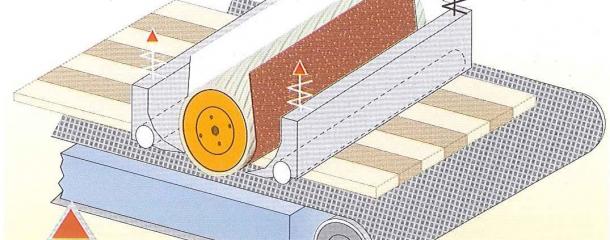

CalibratingSanding of workpieces to a pre-set thickness, while simultaneously eliminating all irregularities of the workpiece surface. This operation is particularly needed before applying veneer cover layers to wooden panels. By using steel or hard rubber rollers, a dimensionally accurate workpiece thickness is reached, while, at the same time, working with high removal rates. There will be no wash-out effect of the early/late wood portions when sanding softwoods using steel rollers. The rubber hardness is given in '° Shore'. Machine settings

Alternative terms

|

CNC machining centres, robots894

Edgebanding, edge processing627

Saws, cutting machines436

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines201

Sanding machines320

Mechanisation, storage, packing technology199

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131