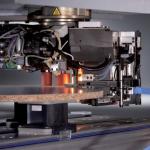

Edgebanding aggregateRefers to a device on CNC-machining centres for coating the narrow sides of plate-shaped workpieces. There are different concepts and types of constructions of machines to achieve this goal. This concept is primarily used for coating freely formed workpieces, since conventional edgebanders can only coat straight edges of workpieces during through-feed. Models with fixed workpiece and movable aggregateThe more frequently used models are similar to conventional CNC machining centers. They do have an additional aggregate, which applies adhesive to the material that will be put on the edges and provides exact gluing. Aggregates, which are exchangeable by the working spindle are used for edge finishing. Often, such machines do have a magazine for coiled edgebands and an automatic cutting device, simpler versions have to be manually loaded with pre-cut stripes. For quality reasons, versions without their own glue application are rather rarely used. There, pre-coated edgematerial would have to be used, which would be re-activated by an infrared lamp or hot air fan. Another feature is the ability to create joint edges. Therefore, an absolutely dimensionally stable and precise rectangular cutting of the edgematerial is necessary. This is especially important for round workpieces, since here edges cannot be glued without joint. There are two different models with movable edgebanding aggregate:

Models with fixed aggregates and movable workpieceLess often used is a solution where no edgebanding aggregate in the proper sense exists. Here, a firmly installed edgebander is integrated into the machine frame as well as devices necessary for edge finishing, like trimming saw, milling machine and scraper. The workpiece is passed by the necessary aggregates for processing by a vacuum lifter, and moved on CNC axes. The advantage of this procedure is that the aggregates, firmly installed in the machine frame, inherently have low vibration. The biggest disadvantage is the high demand on space and the limitations for processing large workpieces, since the workpiece may have to be led around the aggregates entirely. Alternative term

|

CNC machining centres, robots896

Edgebanding, edge processing624

Saws, cutting machines437

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers180

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines321

Mechanisation, storage, packing technology198

Surface coating151

Production lines125

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131