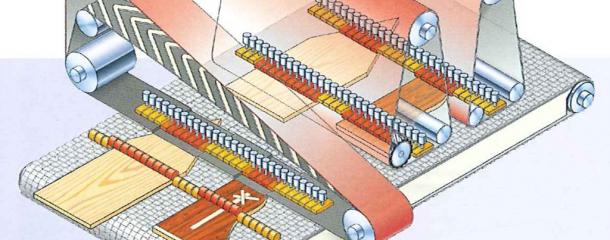

Lacquer sandingSanding after the first painting process with specially equipped wide belt sander and other intermediate sanders. Here, the wood fibers, which erected during the first painting process because of swelling, shall be sheared off. Challenges in sanding already painted workpieces:

Equipment featuresMinimal equipment

Extension to the optimal equipment

Some manufacturers also offer lacquer sanding machines with contact rollers. The used rubber contact rollers are very soft and large in diameter. Differences in the workpiece thickness are compensated by a segmented machine table. Example:

Alternative terms

|

CNC machining centres, robots894

Edgebanding, edge processing627

Saws, cutting machines436

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines201

Sanding machines320

Mechanisation, storage, packing technology199

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131