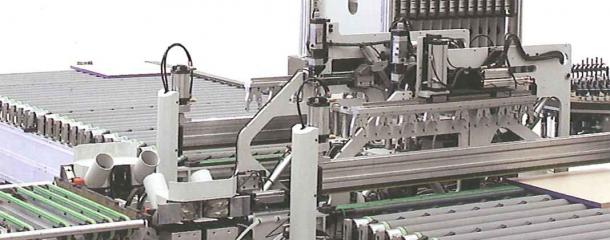

BIESSE EDGE CROSSBANDEdgebanding machines for edgebanding on workpieces, which are mainly produced by transversal processing. The machine consists of a machine frame and a movable carriage. On the carriage there are a piece of a longitudinal conveyor unit, premilling aggregates, edgebanding aggregates and edge finishing aggregates. The carriage moves in the gap between two roller feeders. Working procedure

Performance data

|  BIESSE EDGE CROSSBAND BIESSE EDGE CROSSBAND

| |||||

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131