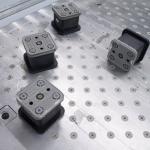

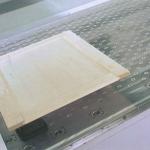

HOMAG GA tableMachine table used by the HOMAG Group for CNC machining centres. It is a plain machine table for the use with suction cups. These can be positioned tubeless and completely free. The GA table is therefore particularly suitable for the production of complicated, free formed workpieces. The GA table is often combined with a suction cup and workpiece positioning system using contour lasers. Mode of operation:The technical principle was developed by the consoles of the K-table and further developed for use over a large area. In the table there is a regular grid of openings for the vacuum closed with magnetic valves. This grid is designed in such a way that at least one solenoid valve is always covered by the suction cup, regardless of the positioning of an associated suction cup. The suction cup are equipped with magnetic stripes which open the corresponding valve when they are covered. In this way, the suction cup can be positioned as desired; only the overlapping valves open. Despite free positioning, the functions "clamping the suction cup on the table" and "clamping the workpiece on the suction cup" can be operated separately. Thus the mode of operation corresponds to a double-circuit vacuum system. The main disadvantage of this system is the high maintenance effort. The valves must be cleaned of dust regularly. For this purpose, the machines are equipped with special blow-off nozzles and a corresponding software macro. However, when processing some materials, especially lumber containing resin, the valves may malfunction. |  HOMAG GA table HOMAG GA table |

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131