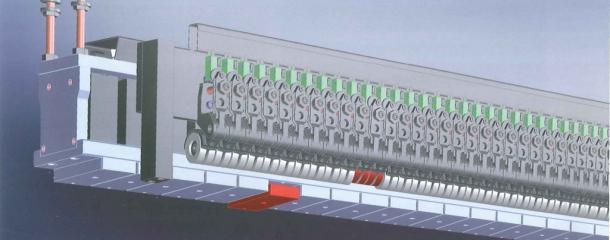

BÜTFERING MPS Magnetic Pad SystemSegmental pressure padThis magnetic pad system is a segmental pressure pad in which the individual segments (actuators) are lowered or raised electromagnetically. Here, also the pressure of each segment can be controlled separately. Each actuator has two sensors. With their help, the area that is to be sanded is determined. If, because of a workpiece edge, only one of the two sensors is triggered, the control allows this actor to apply less pressure as if both sensors had been triggered (dynamic sanding pressure control). With the help of the control one can specify, which reaction the actors shall perform with what intensity to the triggering of the sensors. IAC (Individual Actuator Control):For demanding sanding processes each segment can be individually programmed.

|  BÜTFERING MPS Magnetic Pad System BÜTFERING MPS Magnetic Pad System

| |||||

Images

Product brochures and leaflets (1)

Aggregates

source: BÜTFERING

©

Segmental pressure pad