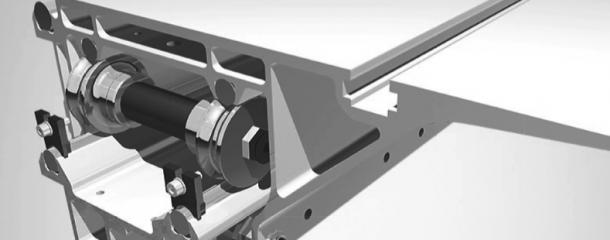

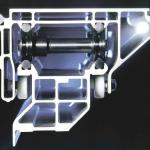

ALTENDORF Sliding tableGuide system used since 1956 for the roller table/sliding table on Altendorf sliding table saws. Construction until about the middle of the 1990s

Further development: steel round rod guide

concerns sliding table saws F45 (2020)Double roller carriage, offered lengths : (2020)

Options: |  ALTENDORF Sliding table ALTENDORF Sliding table |

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131