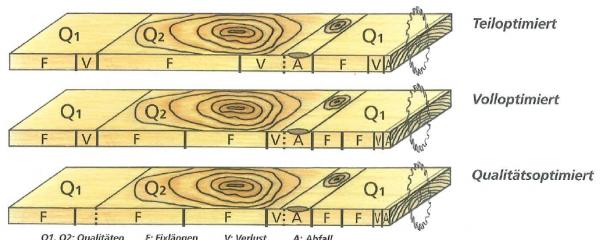

Part optimisationTerm from the solid wood cutting process. Alternatively the term length optimization is used.

It is possible to input a maximum length for waste pieces so that the waste can be reduced. Short workpieces for finger jointing connections are produced as a result of this.

Further information from the field of panel sizing: Special feature of cross-cut saws with upstream measuring stationIf the distance between the measuring station and the saw blade of optimisation saws with upstream measuring station is shorter than the workpiece to be processed, the workpiece is already cut before it can be completely measured. Thus, only a partial optimisation (partial optimisation) can take place. In this case, the required marking strokes should not be set at the end of the workpiece segment, but at the beginning. This requires a change of the marking method in the control (e.g. DIMTER OPTICUT 200). |

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines201

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131