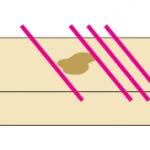

Chalk markingManual marking of wood defects, of intersections or for marking quality grades before cutting. Technical principleThe operator visually checks the workpiece in front of him for the presence of unacceptable wood irregularities or assigns the workpiece areas to individual quality grades. The corresponding areas are marked manually with fluorescent chalk using straight lines. After this workpiece has been transferred to the infeed conveyor system of the machine, a sensor (luminescence sensor) determines the marked areas and transfers the position points to the machine control. Depending on the set operating mode, the wood defects are merely cut out in the subsequent work step or the good workpieces are subjected to full optimisation in conjunction with length and quantity data from a parts list. Condition: Length measurement of the raw workpiece.

Chalk markings

Quality markings - when using a luminescence scanner.

Quality markings - when using two luminescence scanners

Related terms

|

CNC machining centres, robots891

Edgebanding, edge processing630

Saws, cutting machines437

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers179

Drilling, mortising machines135

Presses, clamps, joining machines199

Sanding machines321

Mechanisation, storage, packing technology201

Surface coating152

Production lines127

Heating, drying, waste chopping60

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines135