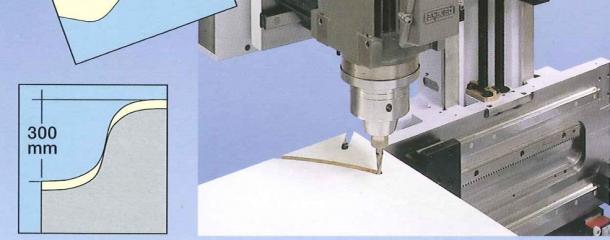

Tracing deviceDevice of double end tenoners to transfer free outlines on a workpiece with a rectangular initial shape. Mechanical pneumatic programmatorConsisting of removable disks, which are directly connected to the gearing. 2 cams on each disc can be attached, one cam for start and end. The discs are sampled by the limit after the cams. On actuation of the limit switch by the cam, the copy routing aggregat goes pneumatically in or out of the workpiece. Simple contours can thus be transferred to the workpiece. Alternative terms

Electronically controlledThe future shape of the workpiece is programmed on a PC and transferred to the workpiece using CN- controlled milling aggregate . Constructive conditionsThe basic requirement is that the milling aggregate can set-in and out in the workpiece (movable at right angles to the feed direction in horizontal plane). The set-in and out is executed by a servo motor, which receives the angular momentum from the CN-control. If the contour is to be continued on the lateral side of the workpiece a second servo axis (CNC-axis) is required, parallel to the feed direction. With their help, the milling aggregate precede the workpiece. Alternative terms

|

CNC machining centres, robots894

Edgebanding, edge processing628

Saws, cutting machines437

Planers, 4-sided moulders187

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology201

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131