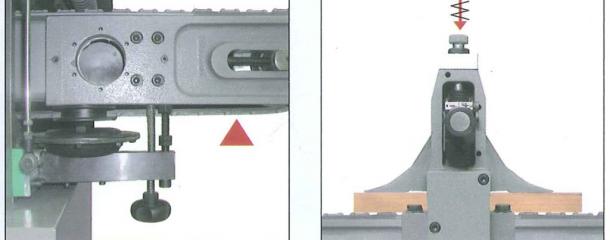

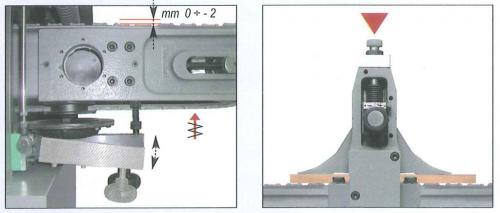

Floating Feed TableThe term "floating table" is used differently. Some manufacturers (e.g. Sandingmaster, Costa Levigatrici) use it to describe the table setting "springy" for the veneer sanding and lacquer sanding in contrast to the table setting "rigid" for the calibrating. Other manufacturers (e.g. DMC, SbF, Viet) refer to tables in which resilient table segments are intended to compensate for the thickness tolerances of different workpieces. These segments can be set rigidly for calibration grinding. See also technical term segmented table. Image 1In the operating mode "lacquer sanding" the pressure rollers are set to rigid and the table to springy. This setting allows the smoothing of workpieces with differences in thickness of up to 2 mm. Image 2In the "Calibrating" mode, the table is set to rigid and the pressure rollers to springy. This allows the infeed of raw panels of different thicknesses, which are ground to the same dimension in the machine. |

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131