ControlBy "control" we broadly mean the general electronic machine components with which the operator sets up the machine and influences its functions. The following overview distinguishes the level of automation in machines according to the kind of control and indicates the switch element which is usually available. Switch controlSwitch element

Contactor controlSwitch elements

Controls programmable from memory (SPS)DescriptionSPS is available in different configuration levels. In the simplest form, a programme sequence is stored unalterably on to a chip in the machine, eg. which sensor sets off which motor when activated (drive motor, control motor). In this way the SPS takes over the functions of the user with contactor equipment, or replaces the mechanical control systems (camshaft, punched tape etc.). The following kinds of control all have SPS at their core. Switch elements

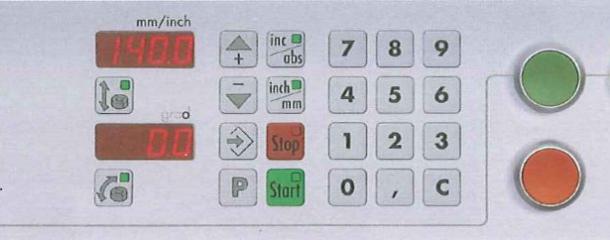

Positioning controlDescriptionParameters such as the cutting length, inclination angle of the tool etc. can be entered via a numerical key panel. Once the START button has been pressed, the strikes / aggregates work automatically to the measurements which have been entered. This kind of control is used mainly in standard machines (sliding table saws,spindle moulders) but also in the adjustment of heavy machines eg. (double end tenoner). There is often an additional option to select fix programmes. Switch elements

Programmed controlDescriptionIn addition to the possibility of entering parameters, this kind of control allows several parameters to be combined to form a programme which can be stored in the control. Even after turning the machine off, the programmes remain and can be accessed after a restart. This kind of control is used in upper-class standard machines and in many medium-class edgebanders and wide belt sanders. It saves time when certain phases of processing are carried out over and over again using the same materials. Thus it is posible, by selecting the corrresponding programme, for a wide belt sander to finish off pine wood panels and within a short time switch to calibrating beech wood panels. Switch elements

With this kind of control and with the following kind, the term "screen control" is often used. CNC and PC controlDescriptionWhen controlling complex processing proceedures which require a number of aggregates or which are to control a whole production line, the SPS is connected not only to an alphanumeric control panel (input) and a display or screen (output) but also to a whole computer (CNC = Computerized Numerical Control). Not only does this simplify the display of the machine status (eg. selected aggregates, set measurements, error indication), at the same time it also simplifies the management and the developing of the machining programmes. The typical application area is in CNC-machining centres and in horizontal beamsaws. An increasing number of edgebanders and double end tenoners are also fitted for this. Switch elements

You can search for the individual controls of each manufacturer in Wood Tec Pedia by going to the "free search" field and then deactivating all search categories apart from "machine control". |

CNC machining centres, robots894

Edgebanding, edge processing630

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines201

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131