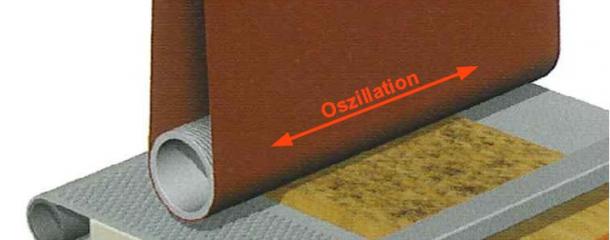

Sanding belts oscillatingProperty and quality feature of sanding machines, which are equipped with an aggregate with sanding belt. The sanding process does not only cause material removal at the workpiece, but also leads to a change of the surface of the sanding belt. The pores between the abrasive particles get plastered with sanding dust, resin and paint components in the sanding dust melt and seal the sanding belt surface, some abrasive particles are broken off. These changes of the sanding belt surface show on the workpiece surface. In addition, the entire sanding width is only rarely used. By a lateral running of the sanding belt (oscillation), these interferences are kept low and a uniform wear of the sanding belt is reached. To let the sanding belt, working parallel to the feed direction, oscillate across the sanding width, the upper guide roller is swung back and forth. If this roller would always be parallel to the feed direction of the workpiece, there would be no oscillation. However, by swinging it a little to the right and a little to the left at one end and in timed intervals, the sanding belt moves back and forth on the guide and sanding rollers. Constructively, it solved in a way that the guide roller is supported rotatably on one end. On the other end, a pneumatic cylinder is located, which causes the swinging movement. The movement of the pneumatic cylinder is initiated by the sanding belt control. The manufacturer of narrow belt sanding machines, Stähle-Hess, used the principle of oscillating aggregates (Stähle-Hess: real belt using oscillation). Here, the entire sanding aggregate moves to the right and to the left in the direction of the sanding width. Picture sources1. Sketch of CB, changed 2. Höchsmann 3. Bütfering, changed 4. Hess, changed |

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131