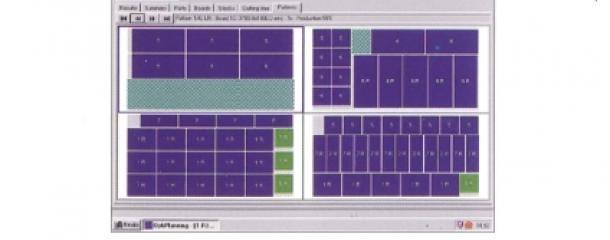

Optimizing panel cuttingSoftware for the efficient exploitation of the panel on beamsaws. Optimisation software reduce the amount of data entry to a minimum. They ensure automated processes beginning from the data transfer, continuing with the optimization of the panelsizing-process and ending with the data output. Typical problem: For a certain project, the most efficient selection of panels needs to be determent. Factors, that need to be considered are the measurements of the raw panels, eventually panels which are on stock and which already have been particulary cut. A complex calculation must be made, which also considers the measurements, the amounts and even the directions of the cut (wood grain) of the current project Software solutions offer the following advantages:

Available software (range)

|

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131