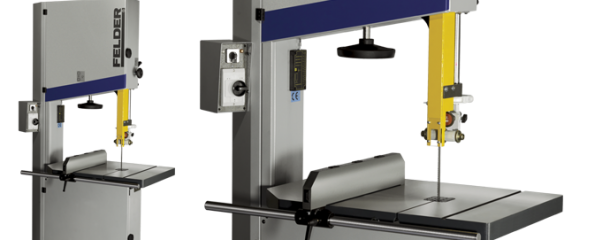

Band sawStandard carpentry machine that is used in many sizes and for practically all crafts. It is not only used for sawing wood, but also for plastics, polystyrene, glass, metal or ceramics. A characteristic feature of all band saws is the welded or soldered saw band running over two deflection rollers. It forms a continuous closed ring and enables endless or uninterrupted cutting. Basic constructionThe construction and principle have remained the same since the 19th century. Differences exist only in manufacturer-specific designs, especially with regard to precision and safety. In the upper and lower area there are two closed hoods which contain and protect the deflection rollers. The tool (band saw blade) is only visible in the cutting area directly above the machine table/workpiece support. The passage height is decisive. Often there is an adjustable stop on this table to guide the workpiece safely. The precision is determined by the guide of the band saw blade in the immediate vicinity of the cutting area. Special featuresIf the band saw works with feed rollers on the machine table, it is a resaw. Angular cuts are possible due to a mitre fence on the machine table. A tilting table allows the operator to make diagonal cuts across the workpiece. Other band saw versions |

Images

Series (376)