PADE UINZERange of linear copy shaper machines from the Italian manufacturer Pade, which mill and sand workpieces on both sides in a single pass PurposeThese machines are used in particular in the production of parts for:

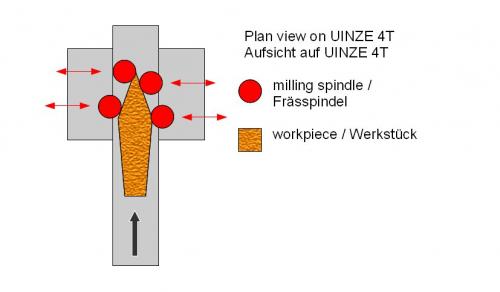

Construction and functionThe core of the machine comprises the centrally positioned machine table from cast-iron, which rests via guides on a frame from thick steel plates welded together. In the case of machines with tracing devices, a hydraulic cylinder implements the linear feed of the table. In the case of CNC-controlled machines, this takes place with a ball screw spindle. The raw parts are held in place on the table by pneumatic cylinders applied from above. In the case of machines with tracing devices it is possible to secure the template on the table. The raw part is placed on the template and secured against moving by means of pneumatic clamping. The working aggregates, which carry out the milling and sanding, are located on the right and left of the table. The aggregates have a cast-iron base body. Guides allow the application of the aggregate to the workpiece. In the case of machines with tracing devices, these guides comprise round bar steel. The CNC-controlled machines have linear guidance. All processing aggregates on one machine side are fastened to a base frame from welded sheet steel, which - with the UINZE machines - are welded with the machine base body, with up to 2 aggregates per machine side. In the case of machines with 3 to 4 aggregates per machine side, the base frame can be tilted away from the machine's base body, together with the aggregates fastened to it. This eases the operator's access to the aggregates for the tool change. The processing aggregates are positioned opposite each other, one after the other at a slight offset. This enables the processing of enclosed forms (e.g. tips of skis and snowboards). The UINZE has essentially been produced for decades in two different versions, which differ from each other in terms of the application of the shape to the workpiece. 1. Shaping through tracingThe workpiece is shaped based on an underlying template. After clamping the workpiece on the template, the table transports the workpiece past the processing aggregates. Adjustable dogs on the table's long sides determine the application points of the processing aggregates. The tracing rollers on the pneumatically applied aggregates follow the shape of the template, and transfer it in this way to the clamped workpiece. 2. Shaping through programmingThe machine is equipped with CNC control and motorised aggregate axes. Prior to work starting, the machine control is programmed with 2D CAD/CAM (digitizer, import of DXF files). After clamping the workpiece, the machine table moves it past the processing aggregates. The workpiece is given its shape by the CNC-controlled application and withdrawal movements of the processing aggregates. AggregatesThe following processing aggregates were available for selection in 2003:

Type overviewMachines with mechanical tracing device

Machines with CNC control

Important options

|

WOOD TEC VALUE

Valuate your used PADE UINZE now for free and calculate the current market price. Quick, simple and independent! Machine valuation | |||||||||||||||||||||||||||||||||

Images

Product brochures and leaflets (9)

Type