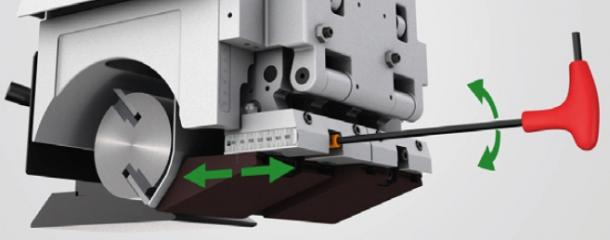

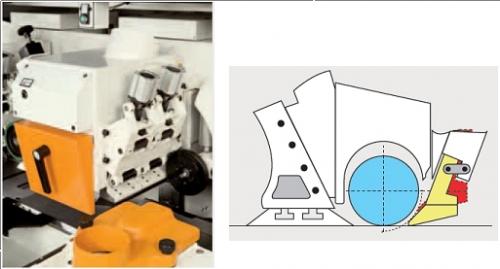

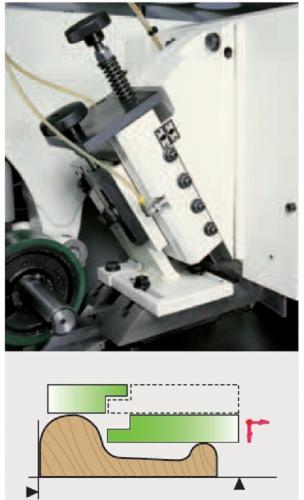

Pressure padsPressure pads on moulders are pressure and guiding devices, which press the workpieces against the machine table or the stops located at the sides. They are located in front or behind the left or upper router heads. To prevent indention from planing they have to be precisely adapted to the diameters.

|

CNC machining centres, robots894

Edgebanding, edge processing628

Saws, cutting machines436

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology199

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131