Power feederSupport device on standard joinery machines to be able to feed workpieces with constant speed and large quantity to the respective processing tool. The following machines can be upgraded with feeding devices:

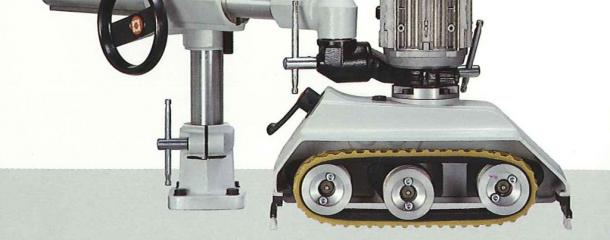

ConstructionThe basic corpus is formed by a gear box, onto which a motor is perpendicularly mounted. The top-acting rotation of the motor is transferred into a horizontally acting movement by the gears. This horizontally acting force is transferred to the drive shafts of the feed rollers via a chain on the other side of the box. Depending on the purpose, rubberized steel or aluminum rollers, corrugated steel rollers or belt discs, which drive a caterpillar band, are used as feed rollers. The number of feed rollers varies between 3, 4 or 6, depending on the model. Depending on the equipment, the feed rate can be changed by exchangeable gearwheels in the chain area or a gear shift lever. Feeding devices are installed on the machine table using a tripod and can be tilted away when they are not used. They can be positioned in height and projection using manual wheels or servomotors. Advantages of feeding devices

Special equipment features

HistoryThe feeding unit has been invented in 1951 by the company HOLZ-HER Reich Spezialmaschinen. Further information: feed in resaws |

CNC machining centres, robots895

Edgebanding, edge processing632

Saws, cutting machines437

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines201

Sanding machines323

Mechanisation, storage, packing technology202

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum135

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines132