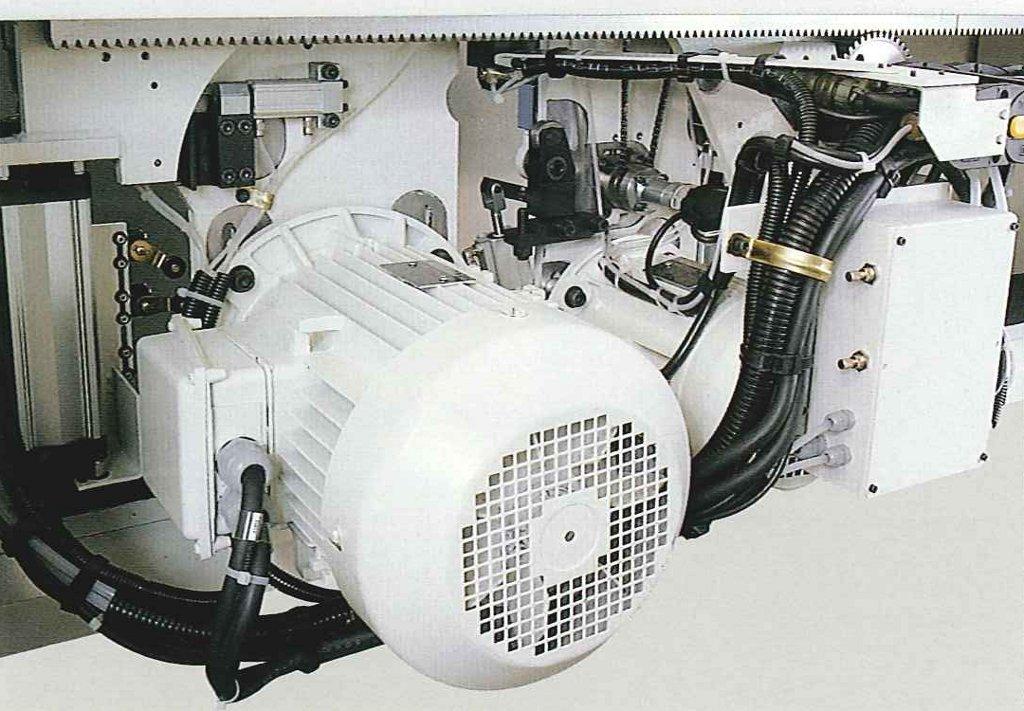

Rack-and-pinion systemThe rack-and-pinion system is the main drive for the generation of translational motion and is part of the rack gears. It consits of a gear, rack and pinion. It is used mainly in cutting machine tools, for example beamsaws, and is a version of the linear drive. Mode of operation and propertiesThe drive is used mostly for feed paths starting at 4 m and is not limited in length. The rotation is transformed into translation. The constant engagement of the pinions into the rack causes a smooth feed, high-quality cuts and constant precision. By the use of continuously variable motors any acceleration gradient can be conducted by the control without mechanical intervention. Zero backslash is enabled by the bias of two pinions, for example via load-limiting springs and two drives. The achievable linear velocity is determined by the pinion diameter and the input rotational speed. By the use of very small pinions acceleration maxima can be achieved. The feed force may be increased by an upstream between the transmissions. The advantage of the system is the simple guarantee of variable strokes and uniform motions. Disadvantages are the low uniform motions and the caused meshing impact. |

CNC machining centres, robots894

Edgebanding, edge processing627

Saws, cutting machines436

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines201

Sanding machines320

Mechanisation, storage, packing technology199

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131