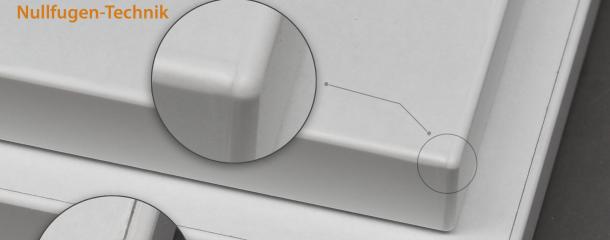

Zero jointThe zero joint, what is it?At edgebanding, the term zero joint refers to a processing result in which the joint between the panel surface and the edge material is not visible to the mere eye. A generally applicable standard for the zero joint does not yet exist (as of August 2020), but there is an unofficial technical method for the evidence of the zero joint, which is referred to as the graphite test. In this test, graphite powder is spread on the plate and rubbed over the joint. If no joint appears after rubbing, the test is passed. For the furniture user, this means that the joint does not collect dirt in everyday use and remains invisible. The first patent for zero joint bonding was registered in 2001 for the kitchen manufacturer Bulthaup, which had developed the laser process in collaboration with the edge manufacturer Rehau and the machine manufacturer IMA. However, laser technology did not reach market maturity until eight years later. At the trade fair LIGNA 2009, IMA presented its first production-ready machine with CO2 laser and HOMAG the first production-ready machine with diode laser. Since then, further technical methods have been developed for industrial and craft manufacturing. Zero joint technologies explained in an understandable waychapter 1: mode of operation chapter 2: edge band material chapter 3: functional layer chapter 4: overview zero joint technologies chapter 5: laser technology chapter 6: hot air technology chapter 7: near infrared technology chapter 8: microwave technology chapter 9: plasma technology chapter 10: hydrogen technology chapter 11: conditions for a successful zero joint chapter 12: zero joint technology for craftsmen chapter 13: zero joint, a critical view |

CNC machining centres, robots893

Edgebanding, edge processing627

Saws, cutting machines436

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131