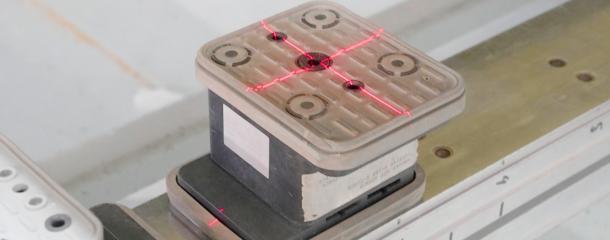

Crosshair laserThe crosshair laser is a positioning aid for CNC-machining centers with pod and rail table or matrix table. It is primarily used whenever it is difficult to position the suction cups by eye and there is a danger of damaging the cups by a collision with the tool, because of complicated milling contours. Mode of operation: A laser is fixedly installed in the aggregates support. The machine can either determine the ideal positions for the suction cups using a software or the operator has to enter them into a program. Then, the machine successively moves to each suction cup position and the projected crosshair shows where the operator has to put the suction cups. Sometimes, the entire workpiece contour can be traced by the laser in a kind of simulation to check the positions of suction cups and workpiece.

Alternative term

|

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131