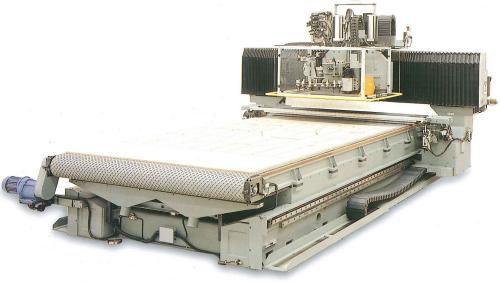

Feed-through technologyFeed-through technology comprises a technical device that transports the workpiece right through a machine. Characteristic here is that the workpiece is fed into the machine on one side and is transported back out of the machine on the other side (usually the opposite site). With the majority of machines processing takes places as the workpiece is fed through. Feed-through technology with CNC-machining centresA feature of CNC-machining centres is the stationary processing of the workpiece. Feed-through technology merely has the function here of transporting the workpiece automatically into the machine and transporting it out again afterwards. The purpose here is often to integrate a stationary machine into a feed through line. However, during the actual workpiece processing the workpiece is usually held in place by stationary clamping devices. The majority of feed-through technologies are realised by belt feeders, which are combined with a pod and rail table. The belt feeders transport the workpiece into the machine and back out again. During processing it is clamped in place by suction cups on the pod and rail table. In some cases the workpiece is moved by grippers, in order to establish the processing movement along an axis. These can essentially also be considered elements of the feed-through technology because the workpiece can be fed into the machine on one side and then back out again on the other. However, true feed-through technology only exists if the grippers are combined with transport devices (e.g. belt feeders). |

CNC machining centres, robots894

Edgebanding, edge processing627

Saws, cutting machines436

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131