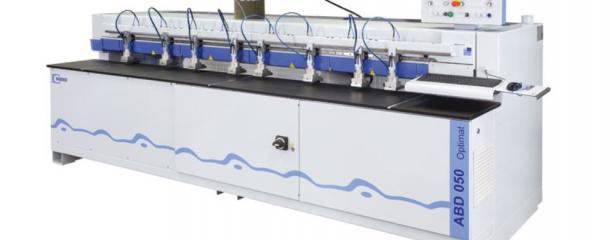

CNC drilling automatDrilling units with CNC-controlled axes for positioning the drilling heads. Depending on the model, the moving axes move the clamped workpiece or the machining units. The holes are not drilled in a single working cycle, as is the case with classic dowel drilling machines, but the entire drilling pattern is drilled individually in a single clamping. For this purpose, a drilling head (or several drilling heads) moves CNC-controlled to each individual drilling position (PTP control). For drilling rows of holes in the surface, several drills are often arranged in a 32mm hole grid in order to reduce the number of drilling cycles and traverse movements required and thus the machining time. In addition to horizontal and/or vertical drilling heads, CNC automatic drilling machines can also be equipped with units for driving in dowels, sawing or inserting fittings. Construction methods

|

CNC machining centres, robots893

Edgebanding, edge processing631

Saws, cutting machines441

Planers, 4-sided moulders187

Routers, shapers, tenoners, profilers179

Drilling, mortising machines135

Presses, clamps, joining machines200

Sanding machines321

Mechanisation, storage, packing technology203

Surface coating152

Production lines127

Heating, drying, waste chopping60

Dust extraction, compressed air, vacuum134

Assembly, worktables16

Lathes29

Tools, sharpening technology94

Equipment, Other machines138