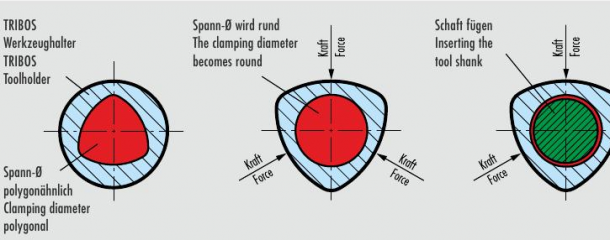

Tribos-Polygon chuckA tool clamping system patented by Schunk GmbH & Co. KG for CNC-machining centres, which offers a very high degree of concentricity. Function - clamping principleThe workpiece holder is not equipped with a round but instead a polygonal locating bore. As soon as this workpiece holder is externally charged with a defined pressure, this changes the shape of the locating bore to a cylinder. Joint changes in the steel are excluded because deformation takes place in the permanently elastic range and below the 0.2% yield point. In this state it is possible to introduce a tool without the application of excessive force. If the external pressure is now reduced again, the internal diameter returns to its original polygonal shape due to the material elasticity, and the tool is clamped through friction-locking. Advantages:

Disadvantages:

|

CNC machining centres, robots894

Edgebanding, edge processing622

Saws, cutting machines438

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers179

Drilling, mortising machines133

Presses, clamps, joining machines202

Sanding machines323

Mechanisation, storage, packing technology198

Surface coating149

Production lines125

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum139

Assembly, worktables15

Lathes29

Tools, sharpening technology99

Equipment, Other machines124