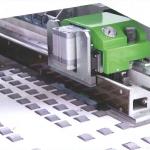

GripperThis term generally stands for a technical device consisting of 2 tongs which open and close in order to hold and transport objects. Grippers on CNC-machining centresReferring to CNC controlled tool machinery such as CNC- machining centres and CNC boring automates, grippers are the device used to hold and transport workpieces. The grippers are used to carry out a processing movement with the workpiece on a linear axis (usually X). Advantages

Disadvantages

Grippers are also used as clamping and gripping devices in other machines, please see: |

CNC machining centres, robots896

Edgebanding, edge processing627

Saws, cutting machines437

Planers, 4-sided moulders187

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines321

Mechanisation, storage, packing technology201

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131