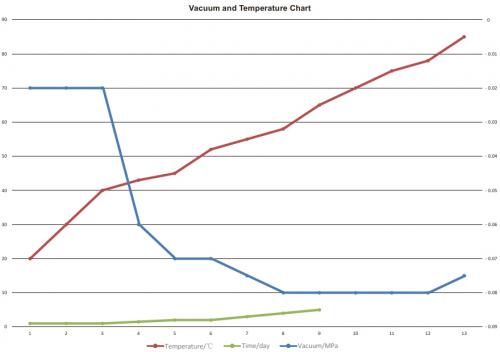

High-frequency dryingWhen drying wood through high frequencies, fresh timber is being exposed to a alternating voltage field during the drying process. This stimulates the water molecules to vibrate. They heat up and evaoprate. The wooden components Lignin and Cellulose, on the other hand, are not stimulated to vibrate. Because of this selective warming process the wood stays unchanged in its material composition, whereas the warming of the entire wooden body may change the properties of the wooden components. As the wood differs from each type of tree to another in its vapour-dissipating structure, different drying programs are necessary. The dissipation of vapour preferably takes place through vacuum technology. They differ from three wave ranges:

In comparison to traditional processesAdvantages

Disadvantages

Common short terms

Alternative process...usually heat up the wood and differ especially in the discharge of steam

|

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131