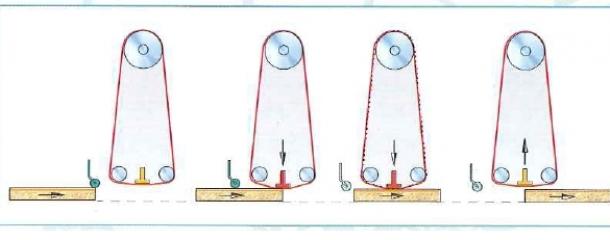

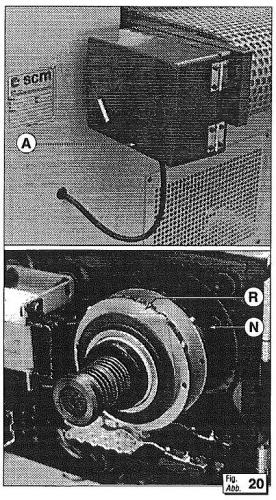

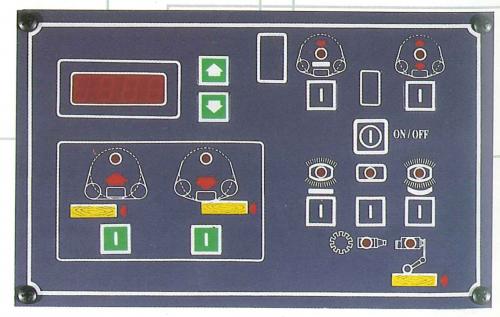

Sanding pad plunge controlledTime-controlled insertion and removal of the sanding pad, while the workpiece passes through the machine. When sanding painted workpieces and thin veneers, there is the risk of the sanding pad to round the front and rear edges when the workpiece enters or leaves the machine or that they are even sanded through (see sanding through). To avoid this, the workpiece is registered at the inlet of the machine and the sanding pad is put onto the workpiece or removed from it controlled by time or way. For this, the operator changes the default insertion or removal times of the sanding pad using an electronic timer or an electro-mechanical cam control. The cam control is often located at the rear pulley of the conveyor bed, the electronic time control is usually integrated into the control panel, recognizable by the mechanical or electronic timer. For computer-controlled machines, the setting up of the insertion and removal times is integrated into the control software. Special featuresWhen changing the feed rate of machines with mechanical feed control and electronic time control, the insertion and removal times have to be recalculated. The company Sandingmaster offers two solutions:

|

CNC machining centres, robots894

Edgebanding, edge processing627

Saws, cutting machines436

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines201

Sanding machines320

Mechanisation, storage, packing technology199

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131