Feed rollerFeed rollers are transport rollers which are part of the feed device on moulders, surface-, thicknessing or four-side planers. Synchronously running, jointly driven rollers, which press the workpiece vertically onto the machine table and transport it horizontally through the machine by means of the rotary motion. In doing so, they should injure the workpiece as little as possible and under no circumstances should they spin. To reduce the frictional forces between the underside of the workpiece and the machine table, sliding agent or table rollers are used optionally. Depending on the application, plain, profiled or toothed feed rollers are used. However, profiled and toothed feed rollers always penetrate into the workpiece surface and can only be used where the surface is subsequently machined by upper horizontal cutter blocks. Design variants and applicationPlain steel rolls

Rubber rollers

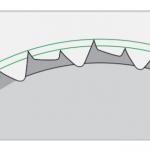

Concave rolls

CeraCoat Roller

knurling rollers

Sharp tooth roller

Freewheel rollers

|

CNC machining centres, robots895

Edgebanding, edge processing624

Saws, cutting machines437

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers179

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines321

Mechanisation, storage, packing technology198

Surface coating151

Production lines125

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131