Part of the workpiece clamping system of CNC machines whith console table or plain table. A suction cup is the element of the machine table, which clamps the workpiece by vacuum. The contact area with the workpiece usually is made of rubber, silicone or similar soft, high friction sealing material. To avoid a continuous air flow, suction cups are equipped with a ball or pin valve. This opens only at workpiece contact and thus clamps it by vacuum suction.

Types of suction cups

There are different types of suction cups, which are optimized corresponding to the table shape and type:

- Suction pods flush with the surface of the console (partly seen as a separate system of vacuum clamping):

- Advantages: The workpiece has a larger contact area and therefore is safer clamped, better supported and vibrations are reduced. The lateral forces are relatively low. Economic types of suction pods can be used.

- Disadvantages: Due to the continuous supports the sizing of the workpiece is only possible with the help of templates without damaging the consoles. This technical type of suction cups is the original system. Today it is rarely used, as modern vacuum systems and vacuum pumps with higher power ensure a sufficiently safe and vibration-free clamping of workpieces.

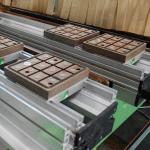

- Vacuum blocks, projecting from the support bars:

- Advantages: The suction cups are projectingly placed on the support bar and thus allow a free sizing of the workpiece. The positioning of the cups is often easier because they are better accessible. By dividing in suction pod basis and suction cup, some systems allow the use of different sizes and shapes of cups on one basis.

- Disadvantage: The additional surface, provided by the consoles, is missing here. As a result there are higher lateral forces, especially at routing. These have to be compensated by higher clamping forces and therefore a higher vacuum capacity. Several economic types of suction pods can not be used.

- Free positioning suction cups: This suction system has pods which are mechanically separate from the support bars. On the entire underside of the cups there are channels for the vacuum. The support bars hold valves in regular distances which open when a suction cup is positioned over them. The distance between the valves is chosen in such a way, that in every possible position the suction cup covers at least one valve. For a few years there was a variant where the valves needed to be opened manually.

- Advantages: The suction cup can be freely positioned on the supports, it can be removed or additional ones can be used without any effort for installation.

- Disadvantages: Relatively expensive system, the additional valves may increase maintenance costs.

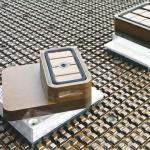

- Double action vacuum cups: Special version for free positioning on plain machine tables. Both the bottom side and the top side of the suction cup are designed as vacuum pod. So the pod can fix itself with the bottom cup on the machine table and with the top cup it can clamp the workpiece. There are different models of this type of vacuum cups: - The vacuum cups are equipped with vacuum hoses, which can be plugged into vacuum outlets in the machine base. - The machine table has holes (connected to the vacuum system) in regular distances, which can be opened or closed by plugs. Such a system is also used on matrix tables. - In the machine table there are automatically opening valves which release the vacuum if a Suction cup is positioned above them.

1-circle-system

A vacuum is created only when the workpiece lies on the suction cups. Thereby the workpiece is hold on the suction cup and the suction cup is hold on the machine table at the same time (console table)

2-circle-system

The suction cup is prefixated at the bottom of the machine table by a separate chamber. This should prevent the slipping of the cups, when the workpiece is applied. The second vacuum circle thus holds the workpiece on the cup and also on the machine.

Alternative terms