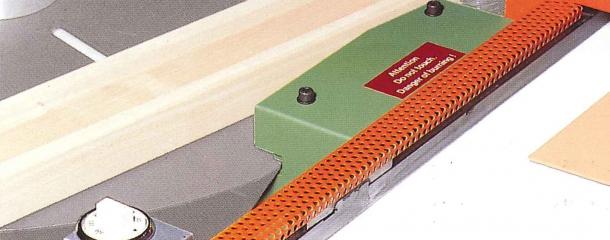

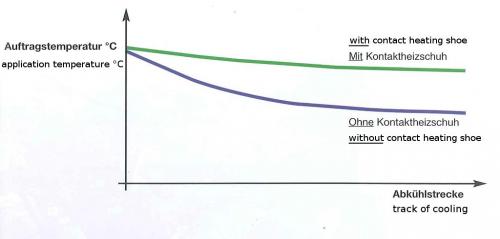

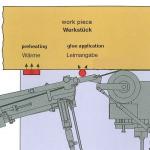

Preheating zoneModule on edgebanders which is there for the heating of the workpiece edge before the edgebanding process. Critical to the strength of the glue connection between the plate and the lipping is that the glue infiltrates the plate material and does not set too fast. For this reason, the workpiece edge can be heated with the help of the preheating zone before the gluing zone. Preheating zones thus replace the slow heating of cold workpieces in the workshop. Another possibility to prevent the too rapid cooling of the adhesive is a glue reactivation by a radiant heater between the adhesive application unit and the pressure zone. The company Brandt uses this system under the name infrared hotmelt activation. Heated infeed fenceDue to the contact with the infeed fence by sliding along, the workpiece edge is heated. Infeed fences can be heated by an internal electric heater (e.g. IMA) or by a hot air fan (e.g. HOLZ-HER). This type of preheating zone can be primarily found on machines of former construction periods. Infrared emittersThe workpiece edge is heated without any contact, by heat radiation, i.e. the heat is generated on impact of the radiation from the company Brandt on the workpiece edge. This type of preheating zone is increasingly used. Depending on the wavelength of the radiation, more ambient air (mainly dark radiation, long wave) or the workpiece material (mainly light radiation, short wave, identifiable by the glaring light in the machine inlet) is heated. Alternative terms

|

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131