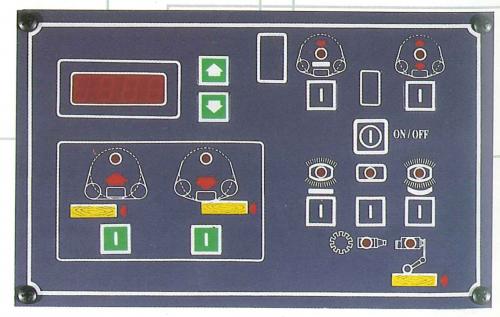

Jump-in controlBy means of the jump-in control working units can be delivered to an exactly defined date. As well as additional devices like blow nozzles, spraying device and like can be switched on and off workpiece-independently. The following three deployment parameters play an important roll in jump-in controls:

Fundamentally there are two kinds of deployment control:

applicationPreferred for machines, on which the workpieces pass in the course of their processing the single woking units on a through-feed machine.

|

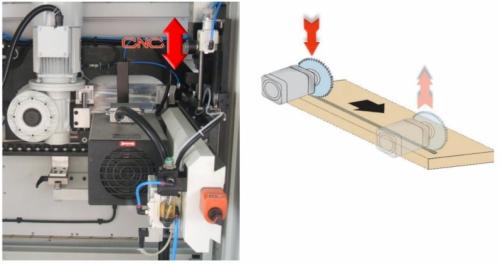

CNC machining centres, robots898

Edgebanding, edge processing624

Saws, cutting machines438

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers180

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines321

Mechanisation, storage, packing technology198

Surface coating152

Production lines125

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131