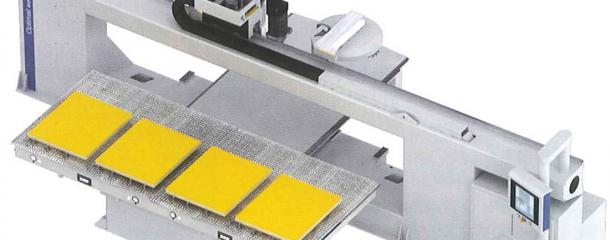

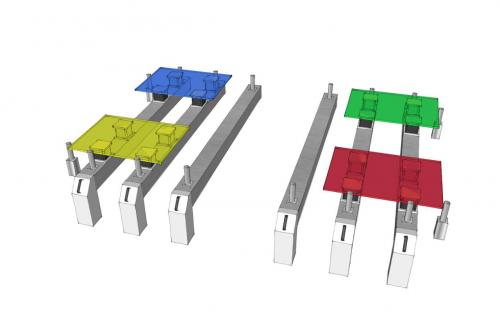

4-field processingIt is a form of processing on multiple fields, where the machine table can be divided into 4 independent zones, which each have their own workpiece reference point with stops. Usually, these zones also have their own vacuum cycles, which can be turned on or off separately, so that workpieces can be put on or removed from the table completely independently. Purpose4 working fields are useful if the machine table shall be used efficiently for small workpieces. Another use is the production of 4 similar workpieces. Then, no separate programs are necessary, the already existing program can be easily transferred to the other zones. Even for processing different, pre-programmed parts an own separate program can be run and edited for each processing station. Even without multi-field processing, an efficient charging of the machine table is possible with small parts. In this case however, each part with its position would have to be pre-programmed. When putting the parts onto the table, it would be crucial to put the workpieces onto the exact spots that were programmed. This would be possible with a contour laser as help for positioning even without stops. However, there still remains the higher programming effort. Also, when exchanging just one part , a completely new program would have to be read in. |

CNC machining centres, robots895

Edgebanding, edge processing624

Saws, cutting machines437

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers179

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines321

Mechanisation, storage, packing technology198

Surface coating151

Production lines125

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131