Butt joint gluingSignifies a certain way of coating the slim sides of panel-shaped workpieces with edge material ("edge adhesive") which are mostly deployed with non-rectangular workpieces. If rectangular panels are being coated in the throughput on an edgebander with edge material, the ends of the edge belt bump together on the edges at most. The exact fit of the thrust will be created by the chop sawing unit with which one rounding can be milled with the edge rounding machine in order to create a visually-appealing hemline. If no rectangular workpieces are to be coated, it's not possible any more. Particularly with panels with round shapes a joint must be created at a circumferential coating, where beginning and end of the edge belt meet. This can e.g. take place with an edgebander on CNC-machining centres. With this either the exact length of the edge belt by means of the workpiece contour can be pre-calculated and automatically cut or the beginning of the edge belt will be recognized via a key-setting and only then the final length will be cut at first. With special edgebanders for molded parts the exact cutting and the fit of the joint takes place manually. |

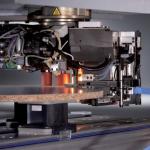

CNC machining centres, robots894

Edgebanding, edge processing629

Saws, cutting machines439

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines202

Sanding machines320

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131