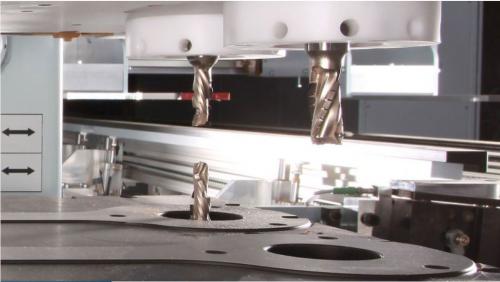

HOMAG ABH 100Throughput machining centre with following possibilities of processing: drilling, milling, grooving and install fittings. The machine can be included in the process as production cell or in complete production lines Technical data (2017)

Equipment features

|  HOMAG ABH 100 HOMAG ABH 100

| |||||||||

CNC machining centres, robots893

Edgebanding, edge processing631

Saws, cutting machines437

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines201

Sanding machines322

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131