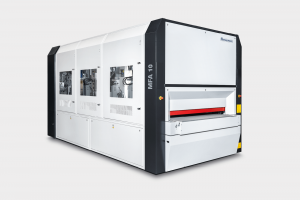

HEESEMANN MFA 10 OSR IIHEESEMANN orbital sander based on the wide belt sander MFA 10 ConfigurationPreparatory unitsIn the first machine section the calibration of the workpieces is carried out with several contact roller units which are equipped with spirally grooved steel or rubber rollers depending on the material. A downstream longitudinal sanding unit with CSD segmental pressure pad and chevron belt also qualifies the machine for lacquer sanding. FinishingIn the second part of the machine, fine finishing is carried out. A RUT disc brush unit serves to break sharp workpiece edges and a cylinder brush unit removes the RUT sanding marks in the recesses of the workpiece surface. This is followed by two successive oscillating sanding units of type OSR of the new generation (from approx. 2016). The first OSR unit is equipped with a 180 graining sanding belt, the oscillation radius is set as large as possible. This ensures that the transverse sanding marks are broken up over a large area. The second unit provides the finish with a 220 abrasive belt and a smaller oscillation radius. Machine typesWith the help of the combined calibrating and fine sanding machine MFA 10 OSR II the complete processing of the above mentioned workpieces is possible. The orbital sander MFA 10 OSR I with a smaller number of units is only used for fine finishing. |  HEESEMANN MFA 10 OSR II HEESEMANN MFA 10 OSR II

| |||||

Images

Product brochures and leaflets (2)

Types of the series HEESEMANN MFA