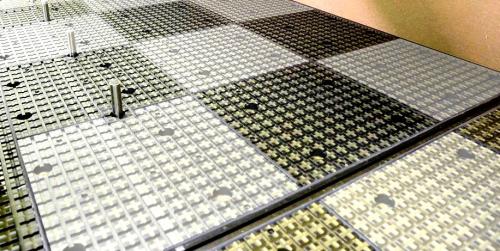

Multi-zone vacuumThe multi-zone vacuum is a device for Nesting machines. Issue:Often nesting machine have a large uniform machine table which is connected to the vacuum pump via a vacuum line. Due to the work with a porous Protection board a large negative pressure occurs during nesting, which is permanently reduced through the volume flow of the Vacuum pump must be balanced. The protection board is usually as large as the largest raw panel to be processed. If smaller formats are to be processed, there is an enormous additional negative pressure in the areas which are not occupied. To avoid this, the heavy, unwieldy protection board must be removed from the machine table. The vacuum areas have to be adapted in accordance with the smaller workpieces and only then can these workpieces be processed. This procedure must be reversed for operation with larger panels. Solution through multi-zone vacuum:The machine table is divided from the outset into individual areas for which the vacuum can be switched on and off separately. This allows both large and small workpieces to be processed without removing the heavy protection board and without additional pressure loss. This can be done through simply flipping levers or pressing switches. Today, partially and fully automated solutions actuated via the control are the norm. |

CNC machining centres, robots894

Edgebanding, edge processing627

Saws, cutting machines436

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines201

Sanding machines320

Mechanisation, storage, packing technology199

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131