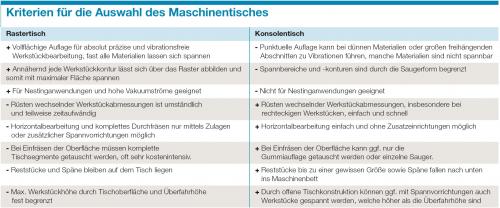

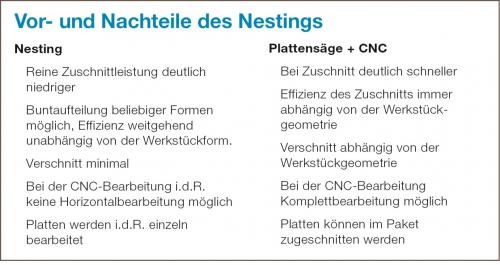

Guide to CNC machining centres | 1The role of the construction form of a CNC machineBecause of changed safety regulations the construction form matters less nowadays than ten years ago. However, it should still attract attention when buying a machine as it's afterall an important detail and some manufacturers like to create the impression of high quality especially with low-priced machines. Cantilever machines which are open on the front side have completely disappeared from the market since 2013 as those are not permitted any more due to safety regulations. More often one may find machines in the more cost-effectiv range where some kind of portal is in function. These are not to be confused with the high-quality, "real" gantry machines, even though one may have got such impression. These simple machines are based on a lightly-dimensioned cantilever, which is driven on one side and supported on the other. Gantry machines on the other hand are symetrically-constructed and have moving gantry machines run on both sides. These constructions are quite stiff and merely ever so slightly tend to vibrate. The most important distringuishing feature: the motors on both sides. The highest-quality, but also most expensive machines with the highest demand of space are fix gantry moving tables. These machines are more likely found in industrial and multi-shift operations. Besides the "classical" construction forms, special types have been created in the last 15 years. The probably most important of them is the one where the workpiece is being clamped with a gripper and moved through the machine. The most-popular for such operation is the vertical design, but there are also machines where the workpiece moves horizontally. Despite the visibly small footprint of the CNC, space for the workpiece needs to be left vacant in front of it and normally behind it as well. Also, because of the gripper and the moveable workpiece there are some restrictions reguarding machining options. For the production of rectangular carcass furniture with predominant drilling work this type of machine construction is a really remarkable alternative. The machine tableMachines with moveable workpiece and grippers have no machine table, on which the workpieces is clamped to. All other machine construction forms have to clamp the workpiece in one or another way. Besides the multitude of special solutions there are two kinds of tables today: the closed Matrix table and the pod and rail table with single vacuum cups. Pod and rail tables are first choice of interior construction workers and manufacturers of carcass furniture which first cut to size their workpieces with the panel saw as well as the ones of most of the stair construction workers. Pod and rail tables exist in different designs. All have the open machine table in common. The workpieces are clmaped by single vacuum cups. They've been alligned on pod and rail as well as matrix tables which can be moved on machine tables. Matrix tables are predominantly used by furntiure manufacturers, mould makers, manufacturers of furniture fronts and moulds as well as all branches which have chosen Nesting technology. Matrix tables is based on closed panels. In this a rectangular grid is installed. In regular intervals the table has apertures through which the vacuum can grip the workpieces. By means of foam rubber cords arbitrary shapes can be sealed around this aperture. If a workpiece is put on, the contour of the foam rubber cord seales off the vacuum and the workpiece is drawn in through suction. Some matrix tables of aluminium are additionally equipped with T-grooves, which serves the mechanical affixing, e.g. of clamping templates. An important reason for furniture and interior construction workers or upholstered furniture manufacturers for purchasing a machine with a matrix table is the Nesting technology. Digression: What about Nesting?As Nesting is a reocurring theme of many operations, the subject can here only be discussed very briefly. During the Nesting process complete panel formats are put on a CNC machining centre from which the finished workpiece contours are milled out as well as processed in the surface. The panel saw is completely obsolete. A special software solution calculates the optimal distribution of workpieces with the lowest possible cut. As general guideline can be said: If rectangular carcass furniture is produced which can be divided over merely few depth gauges, a panel sizing saw is significantly more efficient to work with. However, if many moulds and / or many workpieces different in both width and length are in command, Nesting should prove itself to be an interesting alternative to a classical cut. |

CNC machining centres, robots894

Edgebanding, edge processing627

Saws, cutting machines436

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines201

Sanding machines320

Mechanisation, storage, packing technology199

Surface coating152

Production lines127

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum140

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131