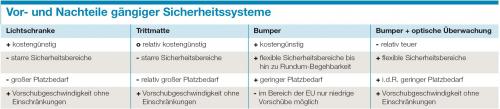

Guide to CNC machining centres | 3Safety and flexibilityThere are different variations with different benefits and disadvantages, even with security systems. The once popular systems light barrier and shut-off mat are nowadays rarely to be found. The use of bumpers, is widely-spread so cushions yield on the moving cantilever/portal, which trigger immediately an emergency stop when the machine is reaching an obstacle. The benefits are obvious: No space for additional safety devices are necessary and the access to the machine is relatively free. With some modern machines, all additional components such as control cabinets and vacuum pumps have been relocated to the machine frame. An all-sided access is possible due to the securing via bumpers. But securing only with bumpers shows a visible disadvantage within the European Union: the legal regulations dictate a relatively-low max. traversing speed. For this reason today most machines are equipped with a combination of several safety systems. The basic principle is the same in all of these system: There is an external safety range and bumpers directily on the body of the machine. If all safety systems are activated, the machine works with max. speed. If the external range is being accessed, the machine reduces the traversing speed to the legally-required measure. Only when the bumpers are touched, the emergency stop is triggered. |

CNC machining centres, robots893

Edgebanding, edge processing631

Saws, cutting machines437

Planers, 4-sided moulders188

Routers, shapers, tenoners, profilers181

Drilling, mortising machines135

Presses, clamps, joining machines201

Sanding machines321

Mechanisation, storage, packing technology200

Surface coating152

Production lines127

Heating, drying, waste chopping62

Dust extraction, compressed air, vacuum134

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131