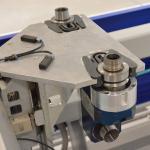

Guide to CNC machining centres | 6Tool changerWhen choosing the tool changing unit one needs to consider that a later expansion of the positions are often not possible or associated to relatively high costs. Even if one only uses roughing and finishing cutters, may have to come use other tools in the future. And whatever cannot be found in the changer is hard to be changed to during workpiece processing. When manufacturing carcass furniture, the number of necessary positions should be easily manageable. In the solid wood processing or even window construction, special attention should be given to the positions. For this not only the absolute number of positions is important but one should already consider, when buying a machine, which tool diameter is to be used later on. The distance between the positions is of huge importance. There're quite compact tool changers with many positions which only allow euipping with end mills. As soon as units or milling tools with high diametres are used, it may well happen that one has to allow room for three positions per tools (the actual position as well as the neighbouring positions). Many manufacturers offer separate, single positions for especially large tools (e.g. sawblades or bulky units) in order to avoid such problem. Even the choice of the changing system may indeed bring certain benefits or disadvantages. Today the following are widespread: Pickup-changerPickup changers are quite cost-effective but come with certain disadvantages. It's mostly firmly-affixed to a position on the machine bed. Those are being approached by the spindle. Thus the toolchanging times are always dependent from the according machining position. That lateral pick-up tool changers cannot be used possibly when a machine is in the process of pendulum machining as the machine would have to cross the safety area, needs to be considered. Disc tool changersDisc tool changers are probably the most wide-spread variation. A disc tool changer consists of a disc on whose edge holding fixtures for the tools are located. Thus capacity is quite limited, as with a high number of tools the discs need to have a high diameter. The tool change always takes place on the same position by the disc simply spinning the needed tool onto the position. Disc tool changers are mostly used as co-moving magazine. It's at its most efficient when the changer co-moves in both X- as well as Y-direction and is located close to the main spindle. The benefits include saving a lot of time when changing. Although size and thus capacity of the changer are mostly limited which is why there is often another changer on such machines. Most of the machines have a disc tool changer, which co-moves in X-direction on the portal. As the X-axis is usually the longest, such cosntruction may save up a lot of time. Simultaneously larger changing units can be used with higher capacities. Partially disc tool changers can also be found as separate, multi-levelled, external magazines. Those are used in order to reserve a huge number of tools for various processings. Although this many tools are often not needed in single programs. Such machines usually have another co-moving changer in command. Before starting a program the machine approaches the external changer and equips the co-moving changer automatically with the needed tools. Chain changerChain changers are usually constructed more elaborately and are hence more expensive than disc tool changers. They facilitate significantly more positions to be vacant at relatively low required space. Hence they are used mostly where a disc changing tool would be difficult to be used due to required space. It would make sense from 18 positions on whereas it should also be mentioned that disc tool changers exist with 24 positions. With a chain changers the positions are on a circulating chain. In order to save space it's mostly arranged on a long basic body. As with tool disc changers, there are chain changers in a co-moving design as well as stationary changing magazines next to the machine. Much more rarely can be found co-moving chain changers close to the main spindle. At a high number of positions, the mere number of tool changes and the supply of the new tools may take up lots of time. Thus additional transfer devices are used which have to positions. One already changes in the next tool during the on-going operation, the other one stays ready in order to take on the tool to be changed. Thus tool changing times can be kept close to constant. |

CNC machining centres, robots894

Edgebanding, edge processing622

Saws, cutting machines436

Planers, 4-sided moulders190

Routers, shapers, tenoners, profilers181

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines324

Mechanisation, storage, packing technology197

Surface coating149

Production lines125

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum139

Assembly, worktables15

Lathes29

Tools, sharpening technology99

Equipment, Other machines124