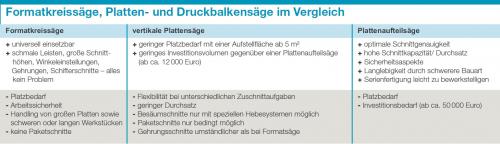

Guide to beamsaws | 1Which saw type is the right one?This question cannot be answered with a sweeping statement. Generally can be said, that sliding table saws can be found in almost every workshop and are indispensable through their universal usability. Vertical panel saws have the advantage towards sliding table saws to require very little space. Equipments such as pre-scoring units, feeding unit, panel lifting systems for trimming and many more make these machines to a remarkable alternative to horizontal beamsaws. But one can say about the horizontal beamsaws that they have the best cutting quality and additionally have the best cutting capacity. Higher quality is achieved because the workpiece lies on the machine table when cutting and is also gripped by the pressure beam. Several panels can thus be cut in a throughput. Automatic feeding solutions, auch as lifting tables and area storage are unbeatable arguments for a horizontal beamsaw. Hence, the following article will focus on this particular type of machine. An interesting alternative should be mentioned: the pressure bream sliding table saw by Italian provider Fimal sowie SCM. This machine concept merges intelligently the benefits of a sliding table saw and of a horizontal beamsaw. This cutting technology can convince with a low need for space, precise cutting results, good security properties and an interesting price-perforamce-ratio. |

CNC machining centres, robots899

Edgebanding, edge processing624

Saws, cutting machines439

Planers, 4-sided moulders186

Routers, shapers, tenoners, profilers180

Drilling, mortising machines134

Presses, clamps, joining machines202

Sanding machines321

Mechanisation, storage, packing technology199

Surface coating152

Production lines126

Heating, drying, waste chopping63

Dust extraction, compressed air, vacuum141

Assembly, worktables15

Lathes29

Tools, sharpening technology91

Equipment, Other machines131